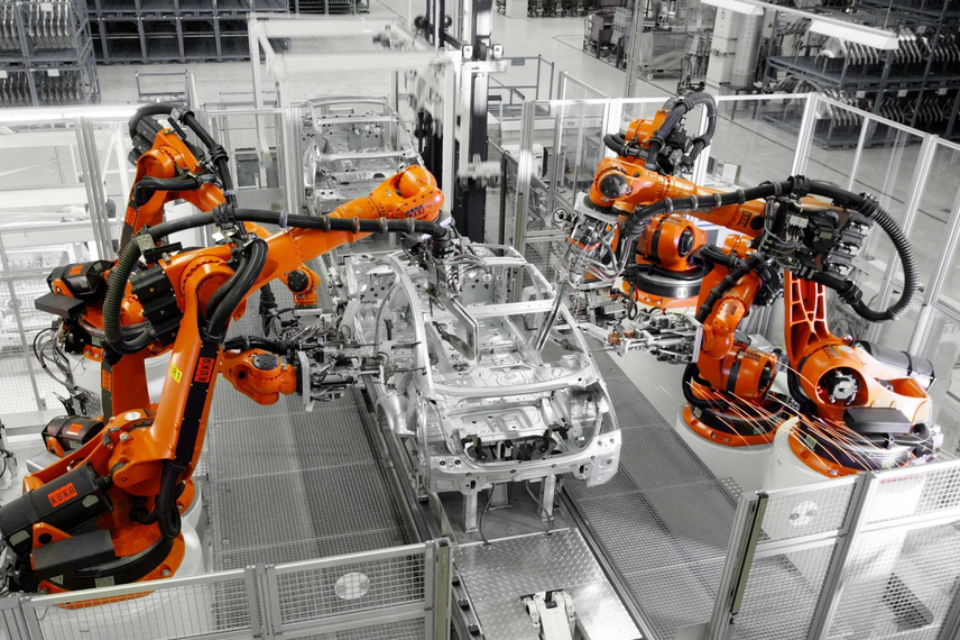

Automation with KUKA in the automotive industry

KUKA AG is an internationally active company with sales of around 3.5 billion euro. Every day, roughly 14,200 KUKA employees at our headquarters in Augsburg and around the world work to ensure that we remain one of the world’s leading suppliers of intelligent automation solutions. Our international customers come from, among other sectors, the automotive industry and general industry. KUKA offers you everything from a single source: from the individual components to fully automated systems.

As a global automation powerhouse, KUKA boasts a comprehensive portfolio of products and solutions. This ranges from individual robots and robotic cells for automated production steps all the way to large-scale customized systems. KUKA focuses on profitable high-growth markets such as automotive and aerospace, and the company has also increased its activity in sectors such as consumer goods and e-commerce. Our solutions enable our customers across the globe to operate more successfully in their respective industries.

Megatrends such as globalization, digitization and demographic changes are transforming the world and the global economy. As a driver of innovation in the automation industry, KUKA supplies the key technologies and solutions for Industrie 4.0 and the factory of tomorrow. This includes sensitive robots for human-robot collaboration, mobile platforms and autonomous navigation.

Global competition and digital transformation increase the requirements on manufacturing companies enormously. While new products and variations are appearing on the market with ever greater frequency, customer expectations on the production of goods are increasingly being influenced by the effortless comparison of offers via the Internet. In order to meet these expectations, manufacturers must ensure great product variety against a backdrop of fluctuating batch sizes.

Adding still further to the pressure are other factors, such as a shortage of skilled labor, rising wage costs and stringent health and safety requirements. Manufacturing companies thus require flexible production systems, the key to which lies in automating production.

Automation means improving the production process by means of machinery and state-of-the-art technologies. As a specialist in the field of robotic automation in production, KUKA enables you to meet the more exacting requirements in terms of speed, flexibility, profitability and added value.

By KUKA you can meet a new automation concepts with human-robot collaboration where in human-robot collaboration (HRC), humans and machines work hand in hand – an entirely new form of automation. While humans control and monitor production, collaborative robots, such as the LBR iiwa, perform unpleasant and non-ergonomic tasks. Thanks to their sensitive capabilities, the robots can work in the immediate vicinity of the human operator and perform production steps with them hand in hand.

In this way, companies can meet their health and safety requirements and employees can be used to perform tasks that call for human strengths, such as the ability to learn, sensory perception or creativity.

The increasing automation of production and the cooperative networking of human workers and machines are set to change the world of work fundamentally. Even in the factory of the future, however, the focus will still be on humans. Robots will not replace humans, but complement their abilities. New kinds of work and new occupations will come into being, particularly at the interface between mechanical engineering and IT.

KUKA stands for Industrie 4.0 made in Germany. With the slogan “iintelligence 4.0_beyond automation”, our goal is to establish smart automation solutions globally in different industries and to pursue their further development. Together with our customers, for example, we want to take the opportunity to support valuable manpower with machinery, secure jobs by means of higher productivity and achieve greater efficiency and flexibility in production.

The automotive industry is very dynamic and requires extreme flexibility from automotive manufacturers. The growing global competition demands smart production systems, combined with flexible logistics systems. They can be adapted quickly and thus also serve the ever-increasing demand for model diversity. In addition to the installation, a simple operation of the system plays an important role. Automotive manufacturers increasingly find that they have to expand their core competencies in areas ranging from automotive industry to mobility or even to re-define those areas. They are only able to stand in the competition if they could cope with developments around Industrie 4.0, demographic change and data-driven production.

Innovations and successes for the automotive industry:

The robots of our KR QUANTEC series are ideal for catering to various requirements of the automotive industry. For example, our portfolio includes the KR QUANTEC nano F exclusive washers, the precise robots of the KR QUANTEC extra family or the powerful industrial robots of the KR QUANTEC ultra family.

Our production facility in Toledo, Ohio, where we use our own technologies, is one of the most efficient car body factories in North America according to the Harbor Report.

Thanks to Swisslog’s expertise we can guarantee innovative intralogistics solutions with just-in-time delivery. This ensures a seamless production process.

KUKA cooperates in numerous research projects with institutions such as Arena 2036 or the E3 Research Fraunhofer Institute, the Technical University Munich and the German Aerospace Center. Over the course of the projects, we have already implemented several applications in our software, for example, KUKA.UserTech in order to ensure optimal data transmission and easy programming.

We work with customers all over the world to help shape and drive forward-looking business models and contract forms such as pay-per-use business models. Please feel free to contact us if you are interested.

We are experts in the automotive sector and support you in the further development of your production and logistics processes with individual production and service concepts.

KUKA ROBOTICS in Romania

Dumbravita is home to KUKA Robotics Romania based sales, services, training and administrative staff, plus from here is supported Bulgaria sales and service area too.Half of the building is dedicated to ”hands-on” experiences with the latest robotics technologies, products and training. Stocks of parts of robots also on-hand to meet ever increasing pressure for fast delivery.

KUKA offers a comprehensive range of services, including collaborative planning, start-up and maintenance to help its customers realize the full potential of KUKA products. In case of urgency, KUKA’s technical support is available 24 hours a day.

Professional training courses from KUKA are tailored to the specific requirements of the customer. Modular in structure, the seminars enable step-by-step qualification on the basis of certified quality standards. At KUKA College, all instructors provide practical training. They have many years of experience and are trained in teaching methodology.

(P)