Vimetco Extrusion, ALRO’s downstream subsidiary, opened new automatic line for aluminium profiles following 10 million Euro investment

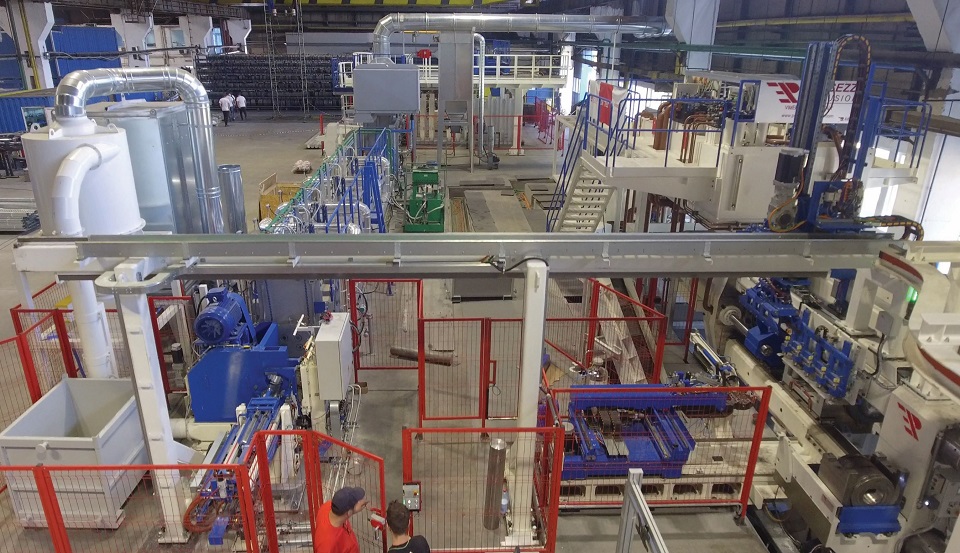

ALRO, one of the largest vertically integrated aluminium producers in Europe, measured by production capacity, announces that Vimetco Extrusion, its downstream subsidiary in charge with the extrusion business completed the installation of a new state-of-the-art press extrusion line, following an investment of approximately 10 million Euro since the start of this project in March 2021. Vimetco Extrusion has just successfully tested the new equipment by extruding the first billets on this line.

This new automatic extrusion line for aluminium profiles is the third one for Vimetco Extrusion. The new press sustains Vimetco Extrusion strategy to increase its production capacity for high value-added aluminium products, thus delivering to its customers an extensive portfolio of customized solutions

“ALRO Group believes that focusing on strategic investments, processes optimization, and cost control represents a suitable and reliable strategy to support our business and help us navigate through these challenging times. This strategy applies to all our subsidiaries, and Vimetco Extrusion’s completion of a new automatic extrusion line is the latest example”, said Marian NĂSTASE, Chairman of ALRO’s Board of Directors. “This is yet another step towards increasing the portfolio of high and very high value-added products, while consolidating the relationship with our customers by offering them a reliable, long-term partner capable of delivering tailored products and services”, added Marian Nastase.

The 7” extrusion line is highly efficient in terms of production capabilities and reduced energy consumption. Thus, the entire process is automated, being able to extrude profiles up to a length of 60 meters, with a speed of 50 meter/minute, while having the lowest guaranteed gas consumption on the market and being equipped with an efficient energy-saving system, as well as with independently operated water and air-cooling zones designed to efficiently allocate resources.

The new extrusion line will increase Vimetco Extrusion’s yearly production capacity by 11,000 tonnes, reaching a total annual capacity of 35,000 tonnes by the end of 2022.