Schaeffler presents innovative multi-material 3D printing systems

From tomorrow, Schaeffler Special Machinery, the Schaeffler Group’s special machine construction unit, will be showcasing its portfolio of turnkey production systems at automatica 2023, the leading international trade fair for intelligent automation and robotics.

The unique concept for the high-precision production of 3D printed parts comprising a combination of metals and ceramics will be available from 2024. “Our newly developed system concept for multi-material 3D printing represents a milestone in the integration of additive manufacturing processes into our production lines,” says Bernd Wollenick, Senior Vice President Schaeffler Special Machinery. “This solution will allow customers to use innovative material combinations, integrate new functions into components and tools, and provide a higher degree of flexibility in the design of products and tools.”

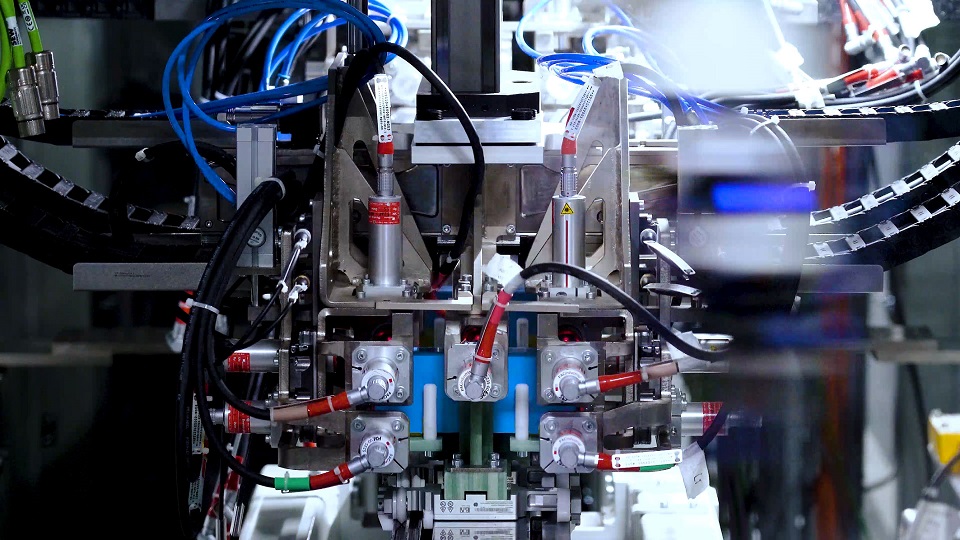

As an example of production concepts in the medical sector, Schaeffler Special Machinery is presenting a solution at automatica that enables the flexible assembly of X-ray tubes, designed for the production of six different variants. In the field of e-mobility, the fully affiliated Schaeffler subsidiary will be showcasing a range of solutions including a system for manufacturing combined electric axle systems comprising electric motor, transmission, and a power electronics unit.

Solutions for battery production, which are also in great demand, will also be on show at the trade fair. “We have already been successful in implementing projects for external customers within e-mobility for the internationally growing battery market,” says Bernd Wollenick. The range includes system concepts used in module assembly for all customary battery cell formats, which can be scaled to various output rates. Schaeffler Special Machinery can provide an agile and rapid response here, delivering turnkey solutions with simultaneous engineering to customer standards with short lead times. Ten customer-specific systems have been developed for automobile manufacturers and automotive suppliers to date, for use in isolating prismatic cells. Highlights include the combination of highly dynamic robots and transfer systems with direct drives, the integration of laser structuring and plasma activation as well as the high-voltage testing of the entire battery cell surface following paint application.